Silver plating is a surface treatment method. After silver plating, the rolling bearing surface is smooth and can form a reliable protective film, effectively preventing wear and oxidation. At the same time, silver plating treatment can also improve the thermal conductivity of rolling bearings, making their performance more stable and reliable under high temperature and high load.

The silver plating of rolling bearings mainly includes various methods such as electroplating, chemical plating, and spraying. Among them, electroplating is a commonly used silver plating method, which forms a uniform silver layer by depositing metal silver ions on the surface of the bearing. The technology of silver electroplating is already very mature, and the thickness and performance indicators of silver can be adjusted according to different bearing types and usage environments to ensure the stability and reliability of silver plating effect.

Application of silver plated bearings:

Aerospace motors, general industrial machinery, vacuum machinery.

1. Silver plated metal holder

In some high-speed and high-temperature applications, steel retainers can be coated with silver to improve lubrication performance and reliability. Silver plating enhances the lubrication of bearings, making them more robust. In the event of lubricant failure or insufficiency, the silver coating acts like a solid, dry lubricant, allowing bearings to continue operating for a short period of time or in emergency situations. The standard silver plating thickness for bearing retainers is usually 0.003-0.005mm. Application example: Silver plated cage for the speed increasing box bearing of high-speed wire rod rolling mill.

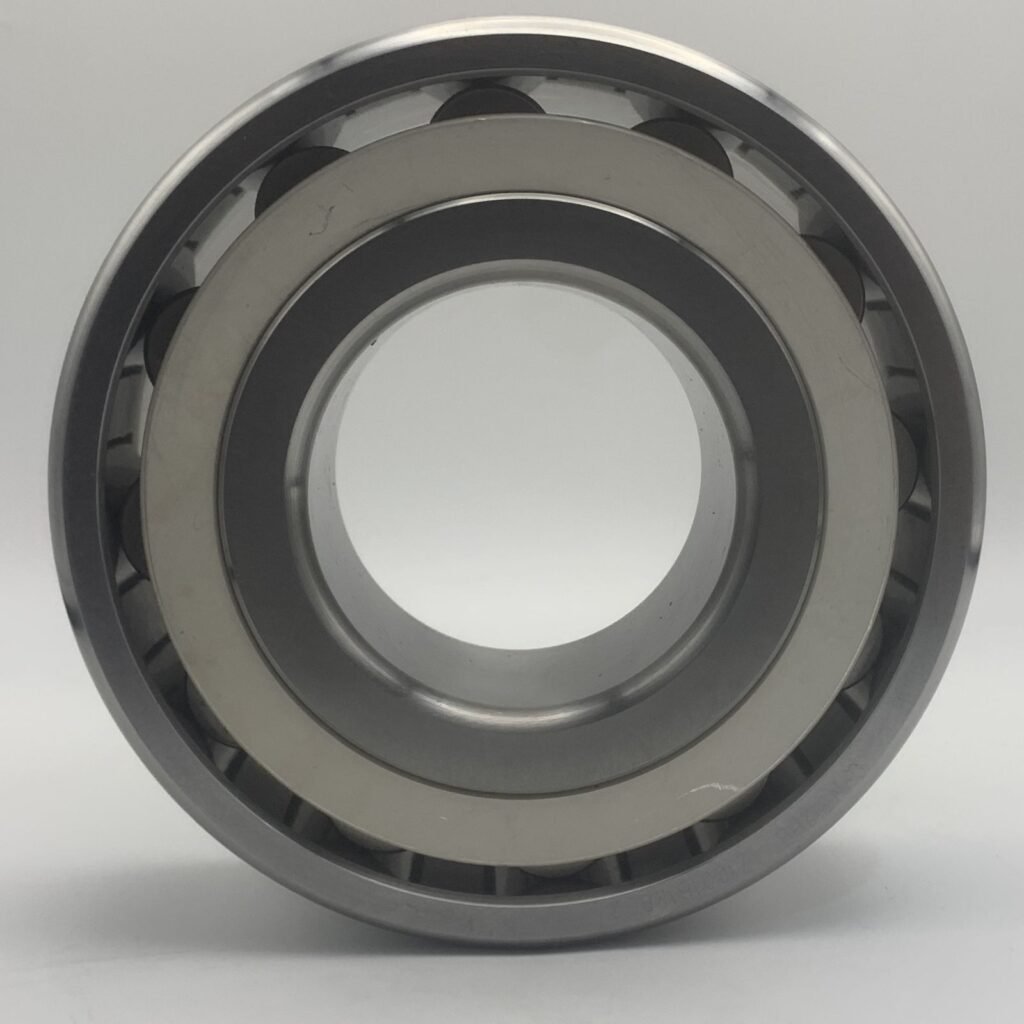

Introduction to the silver plated bearings we have developed

Silver plating is a surface treatment method. After silver plating, the rolling bearing surface is smooth and can form a reliable protective film, effectively preventing wear and oxidation. At the same time, silver plating treatment can also improve the thermal conductivity of rolling bearings, making their performance more stable and reliable under high temperature and high load.

Application of silver plated bearings:

Aerospace motors, general industrial machinery, vacuum machinery.

2、 Silver plating treatment of needle roller bearing rings and rolling elements

In high temperature or vacuum requirements, conventional lubricating grease cannot be used. Silver plating treatment can be applied to the rolling bearing raceway or rolling elements to effectively lubricate the friction surface, enhance bearing wear resistance, and extend its service life.3、 Full ball silver plated bearings

The fully loaded silver plated bearings make full use of the internal space of the bearings, allowing for the use of more balls and greatly increasing the bearing load. With the design of filled notches, they mainly bear radial loads; In the case of adopting angular contact design, the use of pre tensioned double row angular contact bearings allows for the application of bidirectional axial loads, with applications ranging from high-temperature valves in aerospace applications, missile tail support bearings, etc.