The main feature of high speed wire rod production line is high reliability of continuous operation of mill. Due to high unit production,it is required that the bearing used in mill must have higher reliability than normal bearing during in specified inspection.Therefore,the high speed wire rolling mill bearings must meet continuous operation requirements under high-speed and high-impact conditions. Making bearings that can withstand constant production and the prohibition of bearing damage becomes a critical standard for the manufacturers who produce bearings for high-speed wire rolling mills.

Due to the work characteristic of high-speed wire rod mill,the requirement to matched bearing is more strictly.Because high rotation speed of rolling mill,heavy load and large impact force must be hold by bearing,the bearing quality must be reliable and high.The bearings used in speed-increase box,split-speed box, pinch roll, roll box and laying head of finishing mill are imported from west countries and were expensive.

High speed wire rod mill bearings manufactured by Jiayu have steadily been used in high speed wire finishing mill and improved that they have high quality and competitive price compared with bearings produce by American and Germany.There are third,forth,fifth,sixth generation of high speed wire rod mill,and our bearings are suitable fifth and sixth generation finishing mill.

Key technology

1.Considering lubrication,centrifugal force and slip,as well as impact force caused by heavy load.

2.Higher reliability

3.Improved cage design

4.Improved groove curve

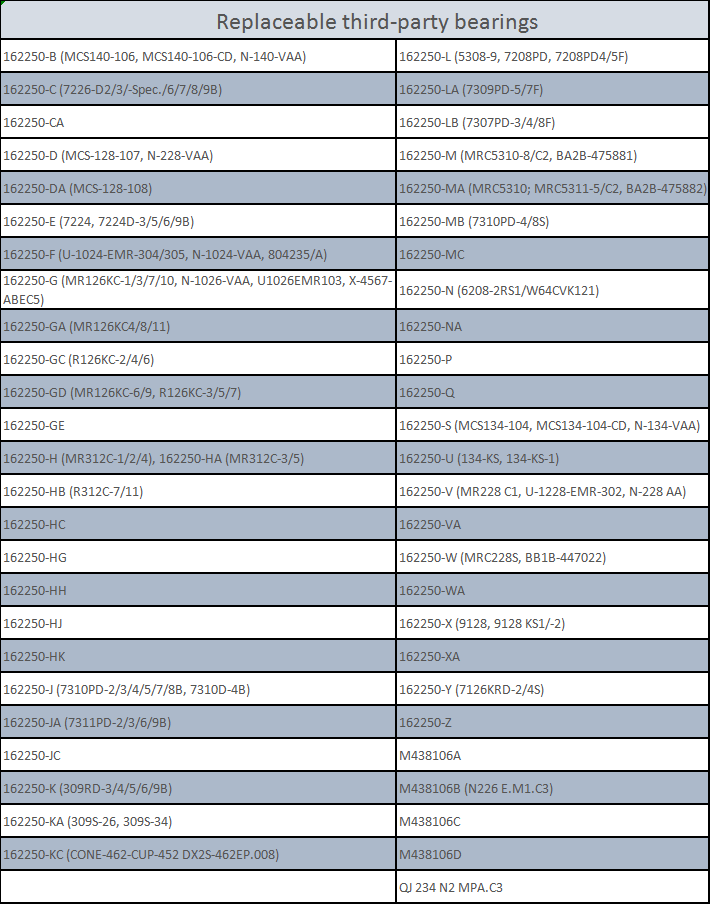

Table 1 High speed wire rod mill bearing dimensions

Applications

| Bearing dimensions of high speed rod mill | |||||||||||

| Code | Bearing model | Main dimensions | Weight | Rated load(KN) | limited speed | Bearing type | Mouting place | ||||

| d | D | B | r | kg | Cr | Cor | rpm | ||||

| 162250B | N140-106 | 200 | 320 | 48 | 2.1 | 15 | 382 | 575 | 3600 | Cylindrical roller bearing | No-Twist Mill Gearbox |

| 162250C | 7266 PD-9/6B | 130 | 230 | 80 | 3 | 14.5 | 308 | 386 | 4500 | Pair angular contact ball bearing | No-Twist Mill Gearbox |

| 162250D | N128-107 | 140 | 220 | 35 | 2 | 5.3 | 211 | 291 | 7000 | Cylindrical roller bearing | No-Twist Mill Gearbox |

| 162250E | 7224 PD-9/6B | 120 | 215 | 80 | 2.1 | 12.4 | 286 | 345 | 5000 | Pair angular contact ball bearing | Long shaft |

| 162250F | N1024 | 120 | 180 | 28 | 2 | 2.8 | 156 | 214 | 9000 | Cylindrical roller bearing | Long shaft |

| 162250G | N126 KC10/7 | 130 | 200 | 33 | 2 | 3.6 | 237 | 299 | 8000 | Cylindrical roller bearing | 1#-6# beve gearbox/driveshaft |

| 162250GA | N126KC11/8 | 130 | 200 | 33 | 2 | 3.6 | 237 | 299 | 8000 | Cylindrical roller bearing | 7#-10# beve gearbox/driveshaft |

| 162250H | N312 C4/2 | 60 | 130 | 31 | 2.1 | 1.9 | 165 | 168 | 11000 | Cylindrical roller bearing | Drive shaft |

| 162250HA | N312 C5/3 | 60 | 130 | 31 | 2.1 | 1.9 | 165 | 168 | 15000 | Cylindrical roller bearing | Drive shaft |

| 162250J | 7310 PD7/5B | 50 | 110 | 54 | 2 | 2.5 | 122 | 102 | 15000 | Pair angular contact ball bearing | 1#-10# beve gearbox/driveshaft |

| 162250K | 309 RD9/6B | 45 | 100 | 50 | 1.5 | 1.9 | 104 | 85 | 16000 | Pair angular contact ball bearing | 1#-6# beve gearbox/Idler pulley |

| 162250KA | 309S 34/26 | 45 | 100 | 25 | 1.5 | 1 | 53 | 32 | 12000 | Deep groove ball bearing | 7#-10# beve gearbox/Idler pulley |

| 162250L | 7208 PD5/4F | 40 | 80 | 36 | 1.1 | 0.8 | 53 | 44 | 15000 | Pair angular contact ball bearing | Roll housing |

| 162250LA | 7309 PD7/5F | 40 | 100 | 50 | 1.5 | 2.1 | 97 | 80 | 15000 | Pair angular contact ball bearing | 3#-10# Roll housing |

| 162250MA | QJ311Y | 50 | 120 | 19.213 | 2 | 2.8 | 83 | 111 | 12000 | Four point contact ball bearing | 1#-2# roll housing |

| 162250MB | 7310 PD8S | 50 | 110 | 54 | 2 | 2.5 | 122 | 102 | 15000 | Pair angular contact ball bearing | Rollhousing/Roll housing shaft |

| 162250S | N134-104 | 170 | 265 | 42 | 2.5 | 8.3 | 316 | 337 | 5000 | Cylindrical roller bearing | Speed increaser |

| 162250U | 134KS | 170 | 260 | 42 | 2.1 | 8.4 | 158 | 149 | 4000 | Deep groove ball bearing | Speed increaser /Splitter gearbox |

| 162250V | N228 | 140 | 250 | 42 | 2.5 | 8.7 | 450 | 569 | 3000 | Cylindrical roller bearing | Speed increaser /Splitter gearbox |

| 162250W | 6228 | 140 | 250 | 42 | 3 | 9.1 | 160 | 154 | 4000 | Deep groove ball bearing | Speed increaser /Splitter gearbox |

| 162250X | 9128 KS2 | 140 | 210 | 33 | 2 | 4.1 | 111 | 108 | 7000 | Deep groove ball bearing | Speed increaser /Splitter gearbox |

Note:For details,please contact us no hesitation