Coated bearings are applied with an additional layer to their surfaces, which enhances their inherent properties. The general purpose of these coatings is to reduce friction, prevent wear, and extend the life of the bearings. The overall benefits of using coated bearings include improved performance, reduced maintenance,improved their corrosion-resisitance performance,and so on.

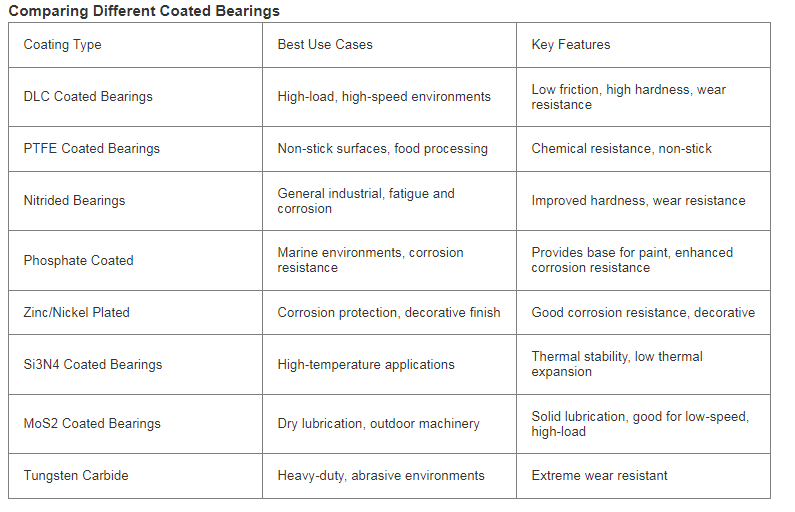

Coated layer type

In order to meet the different bearing applications,there are different coatings,such as silver,phosphated coat,Zinc/Nickel coating,etc.

The following please find the benefits of different coatings

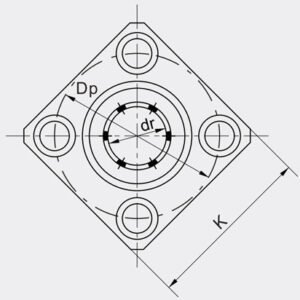

Our products

Our strength and equipment

Depending on rich experience in bearing design, development and manufacture,we provide customers with silvered coating,phosphated coating and zine plating,etc.

The material of rings are 42CrMo or 50Mn,They are treated by quenching and tempering or normalizing.The material of rolling elements is bearing steel.Forging quality is strictly controlled to prevent defects such as cracks,overheat,burning and decarbonisation,etc.For bartch products,rolling expansion is used to get good linear structure and clean and uniform appearance.

Benefits

1.Corrosion Resistance:Coatings protect bearings from rust, making them a great choice for places with moisture and harsh chemicals.

2. Higher Load-Bearing Capacity: Coated bearings can support heavier weights because they spread stress evenly across their surfaces.

3.Enhanced Lubrication Retention: Coated bearings hold onto lubrication better, which means less need for re-lubrication and better performance overall. This is especially important in situations where regular maintenance is hard or rare.

4.Maintenance Reduction: Coated bearings are built to be tough, which means people won’t need to check on them as often and replace them less frequently.